Looking for industrial level sensors in Mexico that you can trust? The best way to get level sensor technology is to buy it straight from well-known manufacturers and approved dealers. Large industry suppliers in Mexico City, Guadalajara, and Monterrey offer complete solutions. International suppliers offer cutting edge measurement systems based on ultrasound and radar. A lot of market share has been won by Chinese companies like GAMICOS, whose high-precision sensors are affordable and meet foreign approval standards like CE, RoHS, and ISO compliance.

Why Sourcing Level Sensors from Global Markets Matters?

Measurement methods need to be accurate, reliable, and cost-effective in the world of industrial technology. Getting level sensors from different parts of the world, like the Americas, Europe, and Asia, gives makers and engineering firms strategic benefits that they can't get from buying from just one area.

With global sources, you can get access to cutting-edge technologies that were made in a variety of different industries. European makers are great at precise engineering and strict quality standards. Asian providers, on the other hand, offer low prices without sacrificing usefulness. American businesses are the best at coming up with new ways to handle signals and connect IoT devices.

Cross-border buying does, however, come with some problems. When you work with sources on different countries, it can be hard to keep track of quality. Lead times can change a lot, which can throw off project schedules. Communication problems and different time zones can make it harder to get the professional help you need.

Diversified buying methods lower supply chain risks and give you more power in talks, even with these problems. Businesses can get options that are specifically made for their needs, like ultrasonic sensors for chemical handling or capacitive sensors for food-grade uses.

Understanding Industrial Level Sensor Applications

Core Technologies and Measurement Principles

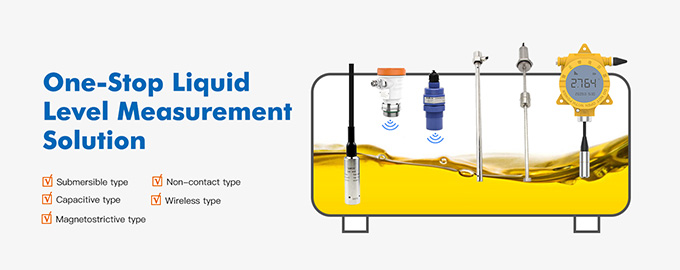

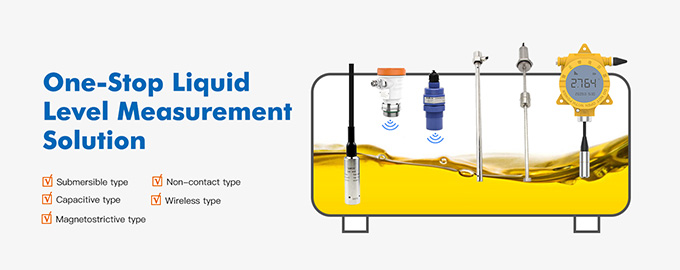

Level sensors use different ways of measuring to get accurate readings of liquid levels in a wide range of industrial settings. Since ultrasonic sensors use sound waves to measure without touching the object being measured, they are perfect for use with acidic or dangerous materials. This technology is shown by the GUT series ultrasonic level meter, which has features like automatic power change, gain control, and temperature adjustments.

Capacitive sensors pick up changes in the dielectric constant and work very well for keeping an eye on liquid tanks. In order to get an exact reading of the level in deep holding tanks, pressure sensors measure the atmospheric pressure. For controlling pumps, float switches are a safe way to make switches.

Industry-Specific Applications

For use in dangerous atmospheres, the chemical and petroleum businesses need sensors that have been certified by ATEX. For pharmaceutical production, clean designs with clean parts and materials that meet FDA standards are needed. When preparing food and drinks, sensors with PTFE diaphragms are needed so that they can work with chemicals.

Submersible level sensors are used in water treatment plants to check the level of groundwater and control sewage pump stations. Environmental tracking systems use LoRa or NB-IoT-enabled wireless sensors to collect data from afar.

Global Market Analysis: Supply and Demand Dynamics

Americas Market Overview

North America has the most advanced sensor systems, with a focus on integrating IoT and watching in real time. The US keeps its industry strong at home while also buying specialized parts from Asia and Europe. Mexico is an important place for the car and industrial technology industries to make things.

The market is mostly interested in sensors that work with Industry 4.0 and have digital communication methods. Companies give more weight to sensors that can predict upkeep needs and have built-in troubleshooting functions. Applications in the car industry are seeing the most growth in the proximity sensor market.

European Market Characteristics

Europe puts a lot of emphasis on precise building and protecting the environment. German companies set the bar for how accurate level sensors are and how stable they are over time. Scandinavian countries are big buyers of environmental tracking systems that can talk to each other wirelessly.

European rules say that CE marks and RoHS compliance must be followed to the letter. For complicated industrial settings, the market prefers sensors that can combine multiple sensors and use advanced signal processing techniques.

Asian Market Dynamics

The Asia-Pacific region is the fastest-growing market for industrial sensors, thanks to a lot of new infrastructure and factories. China makes the most things and keeps quality standards high enough to compete. Japan and South Korea focus on technologies that make things smaller and work with high accuracy.

Asian makers are great at cutting costs without losing quality. There is a lot of demand in the market for solutions that can be changed and for OEM/ODM services that are flexible. Sensor calibration and accuracy requirements continue advancing as manufacturing processes become more sophisticated.

Practical Supplier Evaluation and Procurement Strategies

Quality Verification and Certification Requirements

Effective supplier screening begins with certification verification. Some important qualifications are ISO 9001 for quality management, CE labels for European compliance, and approvals specific to the business, such as ATEX or FM for use in dangerous areas.

Ask for full scientific details, such as the accuracy of the sensors, the temperature index, and data on their long-term stability. Check to see what tests and quality control methods the seller uses. When you can, go to factories to see how they make things and how they handle quality control.

Commercial Terms and Risk Management

Standard minimum order numbers (MOQs) are very different depending on the type of goods and the seller. Most ultrasonic sensors have minimum order quantities of 10 to 50 units, while some specialized pressure sensors may have minimums of 100 or more units. Talk about MOQs that are flexible for the initial testing and approval stages.

For new sellers, payment terms usually include 30% down payment and 70% before shipment. Payment terms of 30 to 60 days may be possible for long-term agreements. Letters of credit are a way to protect big orders from foreign providers.

Standard goods usually take between 2 and 4 weeks to deliver, while unique options can take between 6 and 8 weeks. Allow extra time for shipping and clearing customs in other countries. Keep enough safety stock on hand to keep production from stopping.

Common Procurement Pitfalls and Prevention

Problems with sensor drift and accuracy are often caused by not describing the working conditions well enough. Make sure that external factors like temperature range, chemical exposure, and shaking levels are understood. Before making big orders, ask for trial data that is specific to the program.

Problems with communication methods and sensor interfaces can slow down the execution of a project. Early on in the decision process, make sure that the embedded system and data processing needs are met. Ask for thorough instructions of the interface and examples of how to program it.

When custom sensor designs are made, intellectual property issues may come up. Make clear deals about who owns the idea and how it will be kept secret. Write down all of your expert conversations and requests for changes.

Conclusion

To successfully find industrial level sensors in Mexico and around the world, you need to plan ahead and carefully evaluate potential suppliers. There are many choices on the market, from local wholesalers to foreign makers. Each has its own benefits for different types of purchases. Pay attention to sellers who have professional know-how, quality certifications, and a desire to work with you for a long time.

Whether you need standard ultrasonic sensors or unique pressure measurement options, the best results will come from a careful review of technical specs, business terms, and the supplier's abilities. As industrial technology changes, it's important for providers to be able to adapt to new needs while keeping quality and service performance high.

Frequently Asked Questions

Q1: What are the usual wait times for level control sensors that are made to order?

A: Making a custom sensor usually takes between 4 and 8 weeks, based on how complicated the changes are. It normally takes two to four weeks to customize a standard product in ways like wire length or housing material. Changes that are complicated and involve new sensor designs or transmission methods could take 8 to 12 weeks, which includes testing and approval.

Q2: How do I check the accuracy of the sensors and the certificates of calibration?

A: Ask approved measurement labs for calibration papers that show they can trace back to national standards. Check the accuracy requirements across the whole range of working temperatures. Ask for information on long-term stability and decline. For important apps, you might want to use third-party identification.

Q3: What factors affect the choice of sensors for various workplace settings?

A: Think about the range of temperatures, pressure rates, media compatibility, and dangerous area classes. Chemical protection needs define the types of diaphragm materials and housings that can be used. Levels of electromagnetic interference change how signals need to be processed. Installation restrictions affect the shape and placement choices of sensors.

Partner with GAMICOS for Reliable Level Measurement Solutions

If you're looking for a reliable level control sensor manufacturer, GAMICOS has a lot of experience in a wide range of industry settings. Ultrasonic, radar, and pressure-based measurement options designed for tough conditions are all part of our wide range of sensors. Because our goods are sold in over 100 countries and to tens of thousands of customers every year, we know how important it is for measurements to be accurate and systems to work reliably. Our expert team helps with the whole application process, from the initial design to installation and start-up. Our dedication to quality shows in the goods we sell, which have been certified by foreign bodies and can be customized in many ways. Are you ready to talk about your unique measuring problems? Email us at info@gamicos.com right now.

References

1.Industrial Automation Mexico Market Report 2024, Mexican Association of Industrial Automation

2.Level Measurement Technologies in Chemical Processing, Chemical Engineering Progress Journal

3.Global Sensor Market Analysis: Trends and Forecasts, International Sensor Technology Institute

4.Ultrasonic Sensor Applications in Water Treatment, Water & Wastewater International

5.Pressure Sensor Standards and Certifications Guide, International Instrumentation Society

6.Industrial IoT Sensor Integration Best Practices, Automation Engineering Quarterly