Ultrasonic level sensor is a non-contact level sensor, it can measure water level without contacting the medium. This article is a simple guide for beginners on well understanding ultrasonic level sensor, including its definition, working principle, applications and advantages.

What is an Ultrasonic Level Sensor?

An ultrasonic level sensor, also called ultrasonic level transmitter, is a device that measures the level of liquids or solids by emitting ultrasonic waves and calculating the time it takes for the waves to reflect back. Ultrasonic level sensors work on the principle similar to that of a bat using echolocation. The sensor emits ultrasonic waves, which travel through the air or other medium until they hit the surface of the liquid or solid being measured. These waves then bounce back to the sensor, and the time it takes for the waves to return is measured.

Ultrasonic level sensors have several advantages. They are non-contact sensors, which means they do not come into direct contact with the substance being measured. This reduces the risk of contamination and wear on the sensor. Additionally, they have no moving parts, making them more reliable and less prone to mechanical failure. Another advantage is their compact size, which makes them suitable for installation in tight spaces. Moreover, these sensors are not affected by the properties of the medium being measured, providing consistent and accurate readings regardless of the liquid's viscosity, density, or chemical composition.

However, ultrasonic level sensors also have some limitations. One of the main drawbacks is their relatively high cost compared to other types of level sensors. They can also be affected by environmental factors such as turbulence, foam, and temperature changes, which can impact their accuracy and response time. Additionally, there is often a dead zone near the sensor where accurate measurements may not be possible.

In conclusion, ultrasonic level sensors are a valuable tool for measuring the level of liquids and solids. While they have some limitations, their advantages make them a popular choice for many applications.

How Does an Ultrasonic Level Sensor Work?

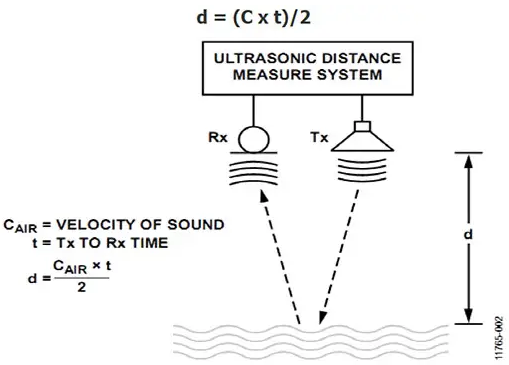

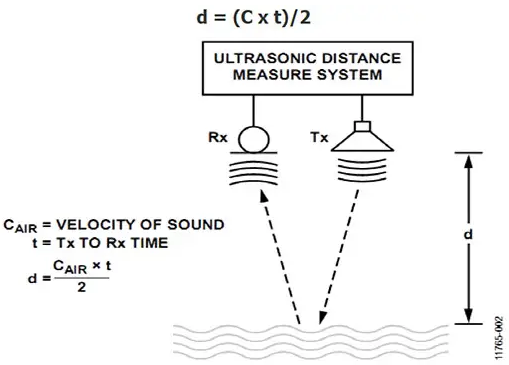

An ultrasonic level sensor operates by emitting high-frequency ultrasonic waves towards the surface of the liquid or solid material whose level is to be measured. The sensor, which contains a transducer that is capable of generating these ultrasonic waves, sends out a burst of energy in the form of sound waves. As these ultrasonic waves travel through the air or other medium, they eventually reach the surface of the material. At this point, the waves are reflected back towards the sensor. The properties of the material being measured can affect the strength and quality of the reflected waves. The sensor is equipped with sophisticated electronics that calculate the time it takes for the ultrasonic waves to travel from the sensor to the material surface and back. This calculation is crucial as it forms the basis for determining the distance to the surface.

Since the speed of sound in air is a known constant, the sensor can use the time calculated in the previous step to determine the distance to the surface. By subtracting this distance from a known reference point, such as the top of the container or a fixed installation height, the sensor can accurately determine the level of the material. This process is similar to how a bat uses echolocation to determine the distance to objects. The ultrasonic level sensor continuously repeats this process to provide real-time measurements of the material level.

Applications of Ultrasonic Level Sensors

Industrial Automation

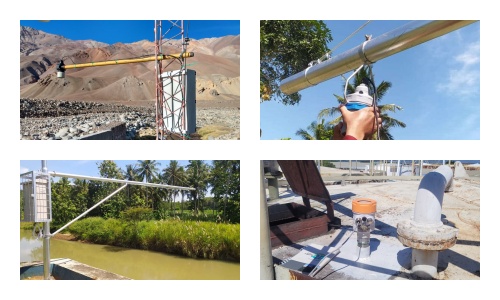

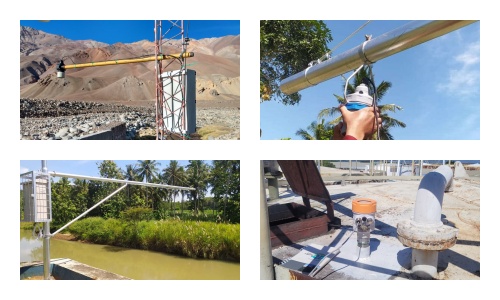

Ultrasonic level sensors play a crucial role in industrial automation by providing accurate measurements of fluids or gases. These sensors enable precise control and monitoring of processes, ensuring optimal efficiency and safety. For example, in chemical manufacturing plants, ultrasonic level sensors can be used to measure the level of various chemicals in storage tanks, allowing for proper inventory management and process control.

Medical Equipment

In the field of medical equipment, ultrasonic level sensors are used to monitor the level of gases and fluids. For instance, in respiratory therapy devices, these sensors can measure the level of oxygen or other gases in tanks, ensuring proper delivery to patients. Additionally, in medical infusion pumps, ultrasonic level sensors can monitor the level of fluids being administered, helping to ensure accurate dosing.

HVAC systems

In HVAC (Heating, Ventilation, and Air Conditioning) systems, ultrasonic level sensors are employed to measure air flow through ducts. By accurately determining the air flow, these sensors help maintain optimal indoor air quality and energy efficiency. They can also detect blockages or malfunctions in the ductwork, allowing for timely maintenance and repair.

Automotive industry

In the automotive industry, ultrasonic level sensors are utilized in fuel injection and air conditioning systems. For fuel injection, these sensors can measure the level of fuel in the tank, ensuring proper fuel delivery to the engine. In air conditioning systems, they can monitor the level of refrigerant, helping to maintain optimal cooling performance.

Agriculture for irrigation systems

In agriculture, ultrasonic level sensors are used in irrigation systems to measure the level of water in reservoirs or tanks. This allows for efficient water management, ensuring that crops receive the right amount of water at the right time. By accurately monitoring water levels, farmers can optimize irrigation schedules and reduce water waste.

Advantages of Ultrasonic Level Sensors

High accuracy in providing readings even in challenging environments.

Ultrasonic level sensors are renowned for their high accuracy in providing readings, even in challenging environments. They can accurately measure the level of liquids or solids regardless of factors such as turbulence, foam, and temperature changes. For example, in industrial settings where there may be varying environmental conditions, ultrasonic level sensors can still provide reliable measurements. Their ability to emit high-frequency sound waves and calculate the time it takes for these waves to bounce back allows for precise determination of the level, ensuring accurate readings even in complex situations.

Non-contact sensing eliminates the risk of contamination or damage.

The non-contact sensing feature of ultrasonic level sensors is a significant advantage. By not coming into direct contact with the substance being measured, these sensors eliminate the risk of contamination or damage. This is particularly beneficial in applications where hygiene is crucial, such as in the food and beverage industry or medical equipment. For instance, in a food processing plant, using ultrasonic level sensors to measure the level of liquids in tanks ensures that there is no risk of the sensor contaminating the product. Additionally, in applications where the substance being measured is corrosive or abrasive, non-contact sensing protects the sensor from damage, reducing maintenance costs and increasing the sensor's lifespan.

Versatile for a wide range of applications

Ultrasonic level sensors are extremely versatile and can be used in a wide range of applications. They are suitable for non-contact applications, especially for measuring the level of high-viscosity liquids and bulk solids. In the chemical industry, they are used to monitor the level of chemicals in storage tanks. In the water treatment industry, they are used to monitor the level of water in reservoirs and tanks. In the automotive industry, they are utilized in fuel injection and air conditioning systems. Their versatility also extends to different types of environments, from industrial automation to medical equipment and HVAC systems. Moreover, ultrasonic level sensors come in various models and configurations, allowing them to be customized to meet the specific needs of different applications.

Easy to install and requires minimal maintenance

Installing ultrasonic level sensors is relatively easy. They are compact in size, making them suitable for installation in tight spaces. Their simple design and lack of moving parts mean that they require minimal maintenance. Once installed, these sensors can provide reliable and accurate measurements for an extended period. In addition, their non-contact sensing feature reduces the risk of wear and tear, further minimizing maintenance requirements. This makes the ultrasonic level transmitter minimal maintenance.

FAQs on Ultrasonic Level Sensor

Q: What types of liquids can this sensor measure? Is it suitable for foaming liquids or liquids with strong agitation?

A: This product is suitable for most water-based liquids, oils, and some corrosive liquids. Measurements may be interfered with for media prone to foaming or with strong surface turbulence. We recommend selecting specialized models with foam-penetration algorithms or installing stilling pipes. Please consult our technical engineers for specifics.

Q: What is the maximum measuring range and accuracy of this sensor?

A: We offer ultrasonic level sensors with various ranges, from short (e.g., 0-5 meters) to long (e.g., 0-40 meters). Typical accuracy can reach ±0.25% of Full Scale. Please check the exact specifications of your selected model on the specific product specification page.

Q: What ambient temperature range is required for the sensor to operate? Does it have explosion-proof certification?

A: Our standard products typically have an operating temperature range of -20°C to +60°C.

Q: Are there any special requirements for installing this sensor? How long is the blind zone?

A: Ensure the sensor surface is perpendicular to the liquid level and avoid interference sources like inlets. All ultrasonic sensors have a measurement blind zone (typically 0.3 to 0.8 meters below the sensor, depending on the model). Installation must ensure the highest liquid level remains below this blind zone.

Q: What types of output signals does the sensor offer? How does it connect to my PLC or control system?

A: We offer various output options, including 4-20mA analog, RS485 (Modbus protocol), and relay switch signals. The standard Modbus RTU protocol allows for easy integration into most industrial control systems.

Q: Does the sensor have a built-in display and programming interface? How are parameters set?

A: Some models are equipped with a local LCD display and buttons for on-site configuration. All models can be conveniently configured and debugged using our free PC configuration software or mobile app (if applicable).

Q: What is the delivery lead time? What is the warranty period?

A: Standard models are usually with short lead times. Lead times for custom products depend on specific requirements. We provide a 12 to 24-month warranty for all products and comprehensive technical support.

Q: What support do you offer if I encounter technical issues or need calibration?

A: We provide full technical support via phone, email, and remote assistance. The products support on-site calibration, and we also offer factory recalibration services with traceable calibration certificates.