- Product

- Pressure Sensor

- Pressure Transmitter

- Level Transmitter

- Fuel Level Sensor

- Ultrasonic Level Sensor

- Radar Level Sensor

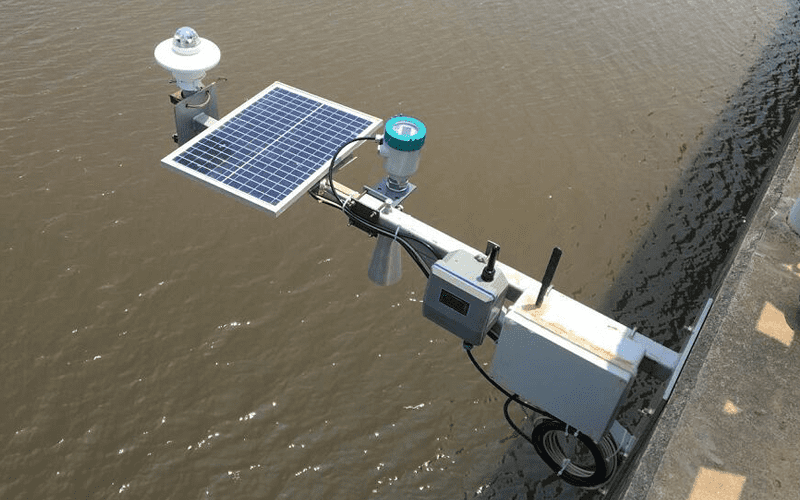

- Water Level Meter

- Accessories

- General pressure sensor Sanitary pressure sensor Differential pressure sensor I2C pressure sensor

-

General pressure sensor

Sanitary pressure sensor

Differential pressure sensor

I2C pressure sensor

- General pressure transmitter Sanitary pressure transmitter High temperature pressure transmitter Anti-corrosive pressure transmitter Industrial pressure transmitter Differential pressure transmitter Digital pressure transmitter Melt pressure transducer Sputtered Thin Film Pressure Transmitter Wireless Pressure Transmitter

-

General pressure transmitter

Sanitary pressure transmitter

High temperature pressure transmitter

Anti-corrosive pressure transmitter

Industrial pressure transmitter

Differential pressure transmitter

Digital pressure transmitter

Melt pressure transducer

Sputtered Thin Film Pressure Transmitter

Wireless Pressure Transmitter

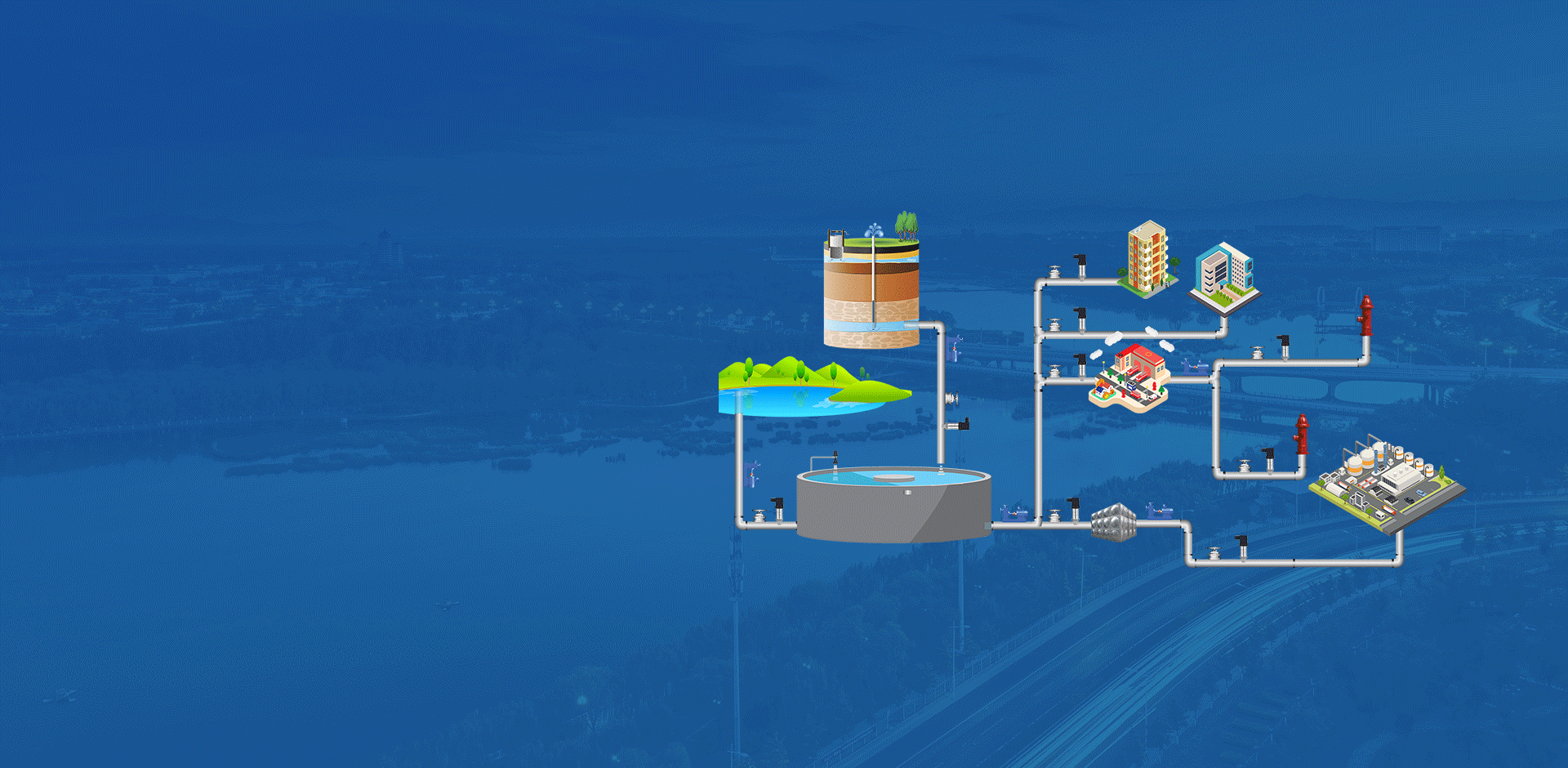

- Submersible level transmitter Anti-corrosive level transmitter Anti-pollution level transmitter Integrated temperature level transmitter Small diameter level transmitter Wireless Level Transmitter

-

Submersible level transmitter

Anti-corrosive level transmitter

Anti-pollution level transmitter

Integrated temperature level transmitter

Small diameter level transmitter

Wireless Level Transmitter

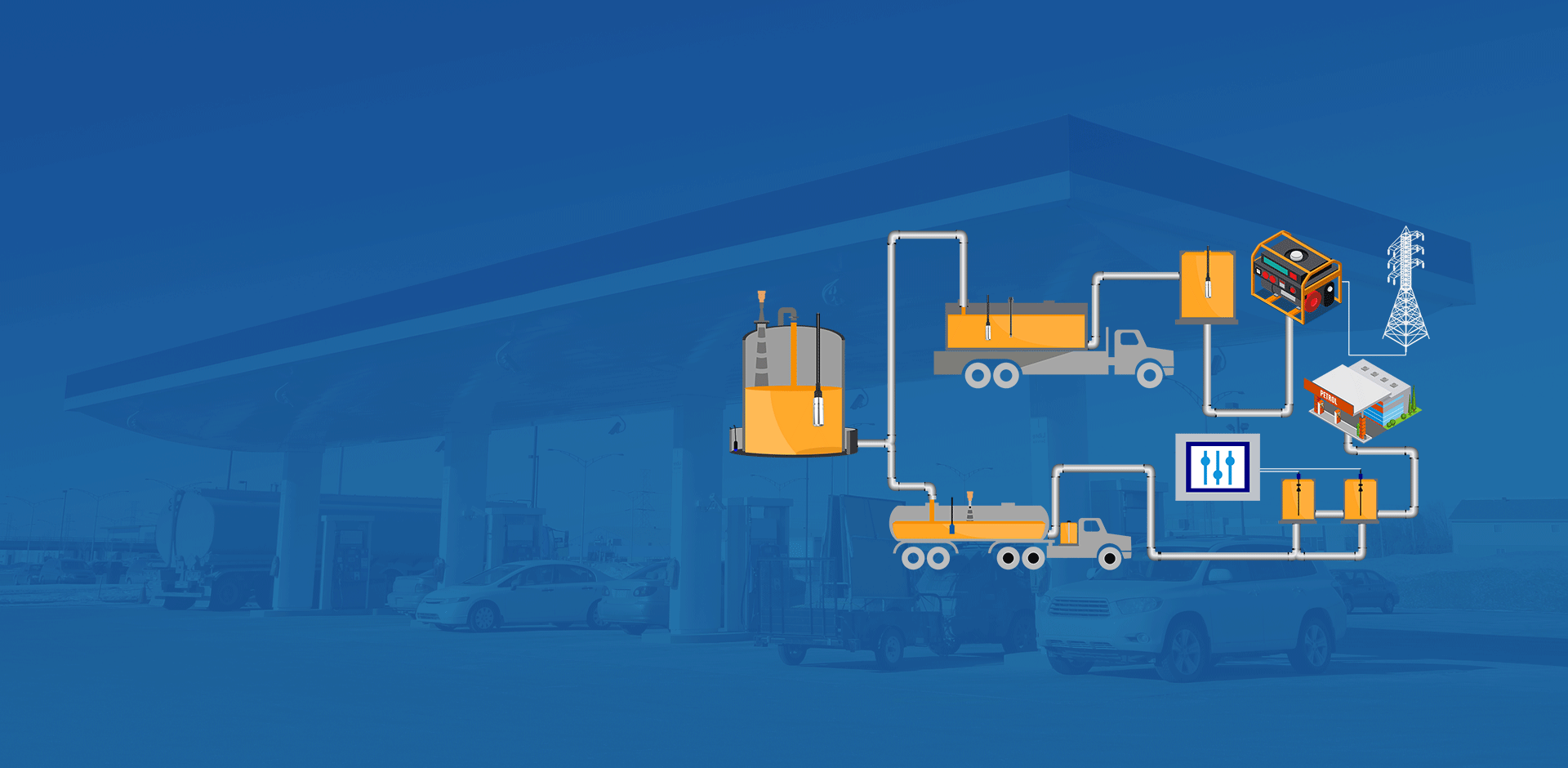

- Capacitive fuel level sensor Mechanical fuel level gauge Reed switch fuel level sensor Magnetostrictive fuel level sensor

-

Capacitive fuel level sensor

Mechanical fuel level gauge

Reed switch fuel level sensor

Magnetostrictive fuel level sensor

- General ultrasonic level sensor Anti-corrosive ultrasonic level sensor Industrial ultrasonic level sensor Handheld ultrasonic level sensor External ultrasonic level sensor

-

General ultrasonic level sensor

Anti-corrosive ultrasonic level sensor

Industrial ultrasonic level sensor

Handheld ultrasonic level sensor

External ultrasonic level sensor

- Guided wave radar level sensor Frequency modulation radar level sensor High frequency radar level sensor

-

Guided wave radar level sensor

Frequency modulation radar level sensor

High frequency radar level sensor

- Solution

- Chemical Vehicles Oil and Gas Food and Medicine Fuel Monitoring Water treatment Machinery Manufaturing Municipal fire Hydrologic monitoring Refrigeration Drilling Exploration

-

Chemical

Vehicles

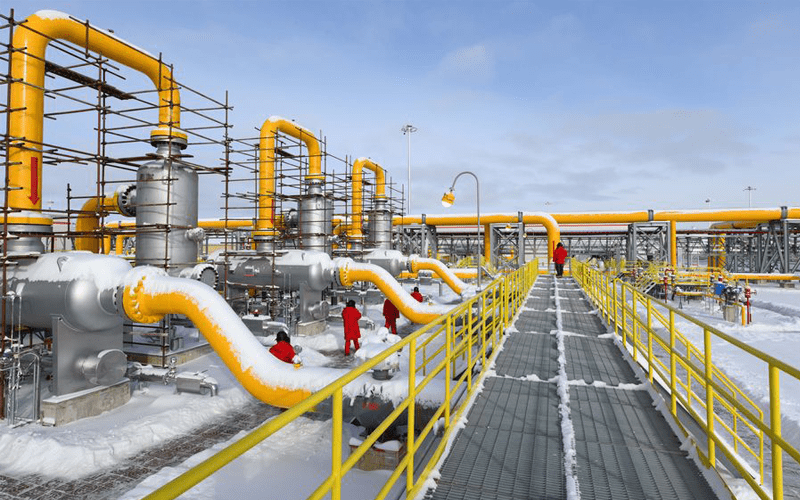

Oil and Gas

Food and Medicine

Fuel Monitoring

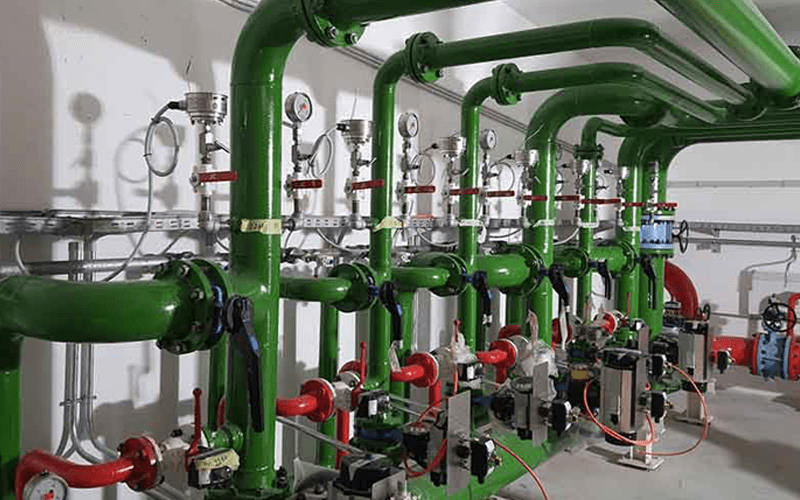

Water treatment

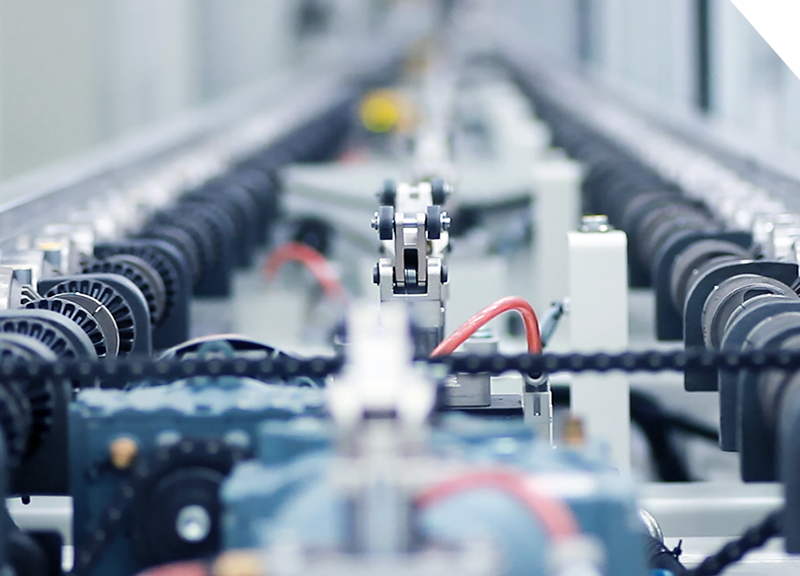

Machinery Manufaturing

Municipal fire

Hydrologic monitoring

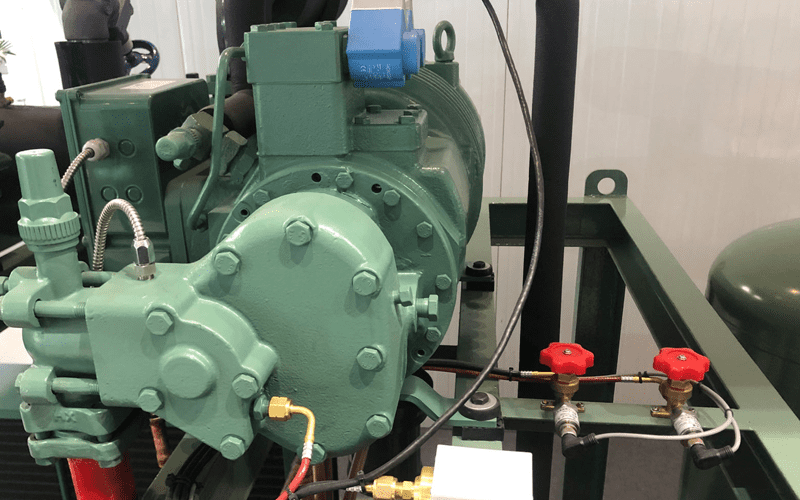

Refrigeration

Drilling Exploration

- Service

- Support

- Blog

- IOT

- About us