Transformer Oil and Capacitive Level Sensor

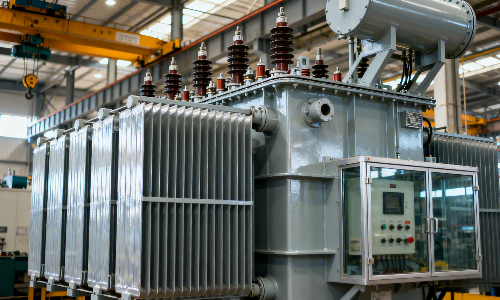

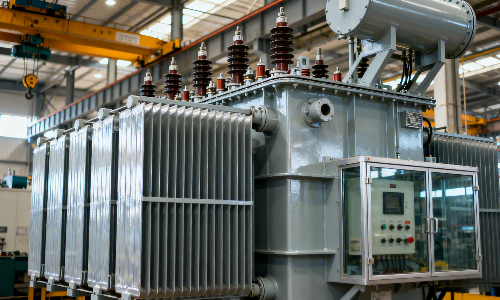

As the core equipment in power transmission and distribution, oil-immersed transformer plays a key role in voltage conversion and energy transfer.It is widely used in power stations, substations, industrial parks and urban distribution networks, etc.

During the Operation of an oil-immersed transformer, transformer oil not only plays an insulating role but also undertakes a heat dissipation function. The oil level is one of the core indicators reflecting the health status of the equipment. If the oil level is too high, it may cause excessive pressure and leakage. If the oil level is too low, the insulation performance will be reduced, the core and winding will be exposed, and then cause local overheating, insulation aging, and even serious accidents such as burning of equipment.

With the accelerated advancement of smart grid construction, the traditional oil level monitoring model that relies on manual inspections can no longer meet the customized requirements of "unmanned operation, remote monitoring, and early warning". An oil level monitoring solution with urgent guidance, high reliability, and adaptability to complex working conditions is needed.

Traditional Oil Level Measurement

Transformer oil level monitoring mainly relies on traditional equipment such as magnetic flap level gauges and glass tube level gauges. These methods have many pain points in practical applications:

1.

Low accuracy and susceptible to environmental interference: Traditional magnetic flap level gauges rely on mechanical float transmission, which is greatly affected by changes in transformer oil viscosity and temperature, and cannot accurately reflect subtle changes in liquid level (such as slow leakage).

2.

Poor reliability and high maintenance costs: The mechanical structure is prone to problems such as jamming and float damage, requiring regular on-site disassembly and maintenance. This not only increases operation and maintenance costs but may also affect power supply due to downtime.

3.

Inability to implement remote intelligent monitoring: Traditional equipment lacks data output capabilities, requiring manual on-site reading of liquid level data. This makes integration into the power system's SCADA (Supervisory Control and Data Acquisition) platform difficult, hindering intelligent management and leading to delayed fault detection (mean fault detection time exceeding 24 hours).

4.

Poor adaptability to harsh environments: In harsh environments such as high humidity, strong electromagnetic interference (transformers generate strong electromagnetic fields when in operation), and low temperatures (winter temperatures in northern regions fall below -30°C), traditional level gauges are prone to reading distortion, component cracking, and other problems, significantly reducing their reliability.

Product Recommendation

To address the pain points of traditional monitoring methods, we recommend our GLTV7S capacitive fuel level sensor. Based on the principle that capacitance varies with dielectric constant, this capacitive oil level sensor enables high-precision, online monitoring of transformer oil levels. Its core technical features and advantages are as follows:

Working Principle

The sensor probe, a coaxial cylindrical structure, is inserted into the transformer tank. As the oil level fluctuates, the ratio of the medium (transformer oil to air) surrounding the probe changes. Because the dielectric constant of transformer oil (approximately 2.2) is much higher than that of air (approximately 1.0), this change in dielectric constant causes a linear change in the probe's capacitance. The sensor's dedicated signal processing circuit converts this capacitance value into a 4-20mA analog signal or an RS485 digital signal, which is then transmitted to the monitoring system for accurate oil level measurement and display.

Product Advantage

1.

High accuracy and stability:Digital signal processing technology eliminates the effects of temperature and viscosity on measurement, achieving a full-scale accuracy of ±2mm and accurately capturing oil level changes as small as 0.1mm.

2.

Adaptability to all working conditions: The probe is made of 316 stainless steel, which is oil-resistant and corrosion-resistant. With an IP68 protection rating, it can operate stably in environments ranging from -40°C to +125°C, strong electromagnetic interference, and high humidity, adapting to different regional climates and working conditions.

3.

Intelligent and remote monitoring: Supports 4-20mA analog signal or RS485 digital signal output, and can be directly connected to the transformer's online monitoring terminal or power SCADA system to achieve real-time oil level display and historical data storage, eliminating the need for manual on-site inspections.

4.

Low maintenance and long life: No mechanical moving parts, avoiding jamming, wear and other failures. MTBF ≥ 8 years. No need to modify the transformer tank during installation (adapt to existing interfaces). Installation time is only 1 hour per unit, significantly reducing downtime.

Customer application cases

Customer Background

A power grid company is responsible for the operation and maintenance of 220kV and 500kV substations. The transformers in 58 of these substations were over 12 years old and faced issues such as low oil level monitoring accuracy and inefficient manual inspections. In 2023, a transformer oil leak at one of the company's substations went undetected, resulting in a four-hour equipment outage. This impacted electricity consumption in three surrounding industrial parks and caused direct economic losses exceeding 8 million yuan. To address this issue, the company plans to upgrade the transformer oil level monitoring systems at 30 aging substations, replacing traditional magnetic flap level gauges with capacitive oil level sensors.

Project requirements

1. Measurement Accuracy: Error ≤ ±2mm, capable of detecting daily oil leaks ≥10ml;

2. Environmental Adaptability: Stable operation in temperatures ranging from -35°C to +40°C (the lowest winter temperature in the province is -32°C) and in environments with strong electromagnetic interference;

3. Data Integration: Supports integration with existing SCADA systems, enabling real-time oil level monitoring and abnormality warnings (warning response time ≤10 seconds);

4. Operation and Maintenance Costs: Equipment lifespan ≥7 years, average annual maintenance ≤1.

Solution

To meet customer requirements, the project employed GAMICOS' GLTV7S capacitive fuel level sensors. The specific implementation plan is as follows:

1. Equipment Selection: Sensor range: 0-300mm (compatible with the company's transformer tank height); Output signal: RS485 (Modbus protocol); Probe material: 316 stainless steel; Protection rating: IP68;

2. Installation: Utilizes the transformer tank's existing level gauge interface (DN50 flange), eliminating the need for tank modification. Installation of a single device takes approximately 40 minutes, eliminating transformer downtime (using a pressurized installation technique, eliminating the need for oil draining);

3. Data Integration: The sensor connects to the substation's RTU (remote terminal unit) via an RS485 bus. The RTU then transmits data to the provincial SCADA system.

Solution Effect

The project was completed and put into operation in March 2024. By June 2025, the results were significant: the capacitive fuel level sensor addressed the pain points of transformer oil level monitoring in older substations. Not only did it offer high accuracy and reliability, it also enabled intelligent management, significantly reducing operation and maintenance costs and the risk of failure. The client plans to expand the solution to its remaining 56 substations between 2025 and 2026, comprehensively improving transformer safety.