Introduction

The importance of choosing a suitable level sensor cannot be overstated. Whether it's for industrial processes, environmental monitoring, or other applications, the right level transmitter can ensure accurate measurements and efficient operations. In this blog post, we will discuss the key factors to consider when choosing a level transmitter.

Importance of choosing the right level transmitter lies in several factors. Firstly, accurate measurements are crucial for proper process control. Incorrect level readings can lead to inefficiencies, product quality issues, and even safety hazards. Secondly, a suitable transmitter can improve operational efficiency by providing real-time data and enabling automated control. It can also help in reducing maintenance costs and downtime. Additionally, choosing the right transmitter can ensure compatibility with existing systems and meet regulatory requirements.

Factors to Consider When Choosing a Level Transmitter

Measurement accuracy

The accuracy of the level transmitter is crucial for ensuring reliable measurements. It refers to the degree of exactness or correctness of a measurement. High accuracy is essential for proper process control. Incorrect level readings can lead to inefficiencies, product quality issues, and even safety hazards.

For example, when choosing a level transmitter, one should consider its resolution. Resolution is the smallest change in the measured variable that the transmitter can detect. A higher resolution transmitter will be able to provide more detailed and accurate measurements. Repeatability is also an important factor. Repeatability refers to the ability of the transmitter to give the same measurement when the same input is applied multiple times. A transmitter with good repeatability will ensure consistent measurements over time.

In addition, the measurement range of the transmitter should be appropriate for the application. If the measurement range is too small, it may not be able to accurately measure the highest or lowest levels. On the other hand, if the measurement range is too large, it may result in lower accuracy.

Range

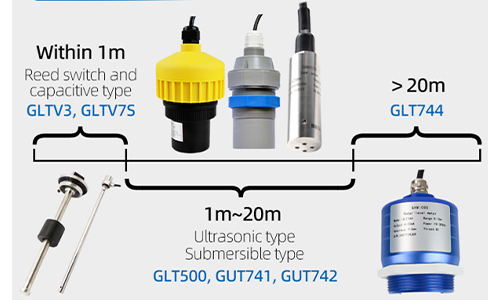

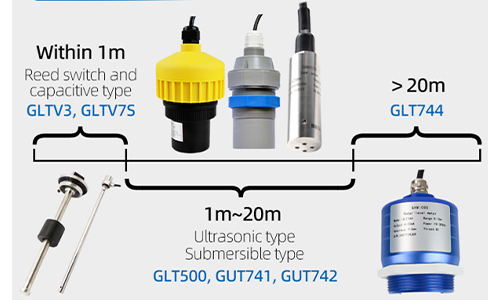

Consider your tank depth before you choose a level transmitter. According to different tank depth, we have different product recommendation.

1)Tank depth within 1m: reed switch and capacitive type

2)Tank depth 1m~20m: ultrasonic type and submersible type

3)Tank depth over 20m: radar level sensor

Application requirements

Think about the specific requirements of your application, such as the type of material being measured, the operating environment, and the installation requirements. Different applications have different requirements for level transmitters. For instance, the material being measured can affect the choice of transmitter. Materials can vary in properties such as conductivity, density, and viscosity. Some transmitters are better suited for certain types of materials.

The operating environment is also an important consideration. Factors such as temperature, pressure, and humidity can affect the performance of the transmitter. For example, in high-temperature environments, a transmitter that is designed to withstand extreme temperatures may be required. In corrosive environments, a transmitter with corrosion-resistant materials may be necessary.

In addition, installation requirements is a crucial factor. The space available for installation, the mounting location, and the connection type all need to be considered. Some transmitters are designed for specific installation methods, such as flange mounting or threaded connection.

Cost

The cost of the level transmitter is an important consideration. However, don't sacrifice quality for price. Consider the long-term cost of ownership, including maintenance and replacement costs. While it may be tempting to choose the cheapest transmitter available, this may not always be the best decision. A low-cost transmitter may have lower quality and accuracy, which can lead to problems down the line.

In addition to the initial purchase cost, one should also consider the long-term cost of ownership. Maintenance costs can include things like calibration, repair, and replacement of parts. Replacement costs may be incurred if the transmitter fails prematurely or becomes outdated.

It's important to find a balance between cost and quality. Look for a transmitter that offers good performance and reliability at a reasonable price. Consider the reputation of the manufacturer and read reviews from other users to get an idea of the product's quality and durability.

Tips for Selecting the Right Level Transmitter

Research different brands and models

When it comes to choosing a suitable level transducer, conducting thorough research on different brands and models is crucial. There are numerous options available in the market, and each brand may offer unique features and advantages. By comparing different models, you can gain insights into their performance, reliability, and user reviews. Look for reviews and recommendations from other users who have already used these transmitters in similar applications. This can help you make an informed decision and choose a level transmitter that meets your specific requirements.

Consult with experts

If you're uncertain about which level transmitter is best for your particular application, don't hesitate to consult with experts in the field. These professionals have extensive knowledge and experience in dealing with various level measurement scenarios. They can provide valuable insights and recommendations based on your specific needs. Whether it's an engineer, a technician, or a consultant, their expertise can help you narrow down your options and select the most appropriate level transmitter. You can reach out to them through industry conferences, online forums, or by contacting professional organizations.

Consider compatibility with existing systems

Compatibility with your existing control systems and displays is an important factor to consider when choosing a level transmitter. Make sure the transmitter you select is compatible with your current setup to ensure seamless integration. This will not only save you installation costs but also reduce the risk of compatibility issues down the line. Check the specifications of the level transmitter and compare them with your existing systems to ensure a smooth transition. For example, if you have a specific type of control system, make sure the transmitter can communicate with it effectively. Additionally, consider the future expansion of your systems and choose a transmitter that can accommodate potential upgrades or additions.

Conclusion

Choosing the right level transmitter is essential for ensuring accurate measurements and efficient operations. By considering the factors discussed in this blog post and following the tips provided, you can make an informed decision and select the level transmitter that best meets your needs.