Pressure sensors play a pivotal role in numerous fields, serving as the crucial “eyes” that monitor and control pressure conditions. They are integral to industrial automation, automotive systems, aerospace engineering, and even our daily lives, such as in smart home appliances. Understanding the key parameters of pressure sensors is essential as it directly impacts the accuracy, reliability, and suitability of their applications. This article delves deep into these parameters to provide you with a comprehensive guide.

Core Performance Parameters

Rated Pressure Range

The rated pressure range refers to the span of pressure values within which the sensor is designed to operate with optimal performance and accuracy. It is the pressure interval that the manufacturer has calibrated and guaranteed the sensor for. For example, in a gas pipeline pressure monitoring application, sensors with a rated pressure range suitable for low to medium pressures might be selected. In contrast, for deep-sea exploration equipment, where extreme hydrostatic pressures are encountered, sensors with a much higher rated pressure range would be required. This parameter dictates the maximum and minimum pressures the sensor can handle while maintaining reliable measurements. Selecting a sensor with an inappropriate rated pressure range can lead to inaccurate readings or even permanent damage to the device.

Pressure Range

The pressure range defines the maximum and minimum pressures that the sensor can endure continuously without significant degradation of its performance or structural integrity. It is related to but distinct from the rated pressure range. While the rated pressure range focuses on optimal operation, the pressure range is more about the sensor’s physical limits. If a sensor is subjected to pressures beyond its pressure range, it may experience fatigue, drift in measurement accuracy, or outright failure. For instance, in a hydraulic press application, knowing the pressure range helps ensure that the sensor can withstand the peak pressures during operation and still function accurately over time. Understanding the relationship between the rated and pressure ranges is vital for proper sensor selection and safe operation.

Damage Pressure

Damage pressure is the threshold beyond which the sensor will suffer irreversible physical damage. Exceeding this value can rupture diaphragms, damage internal circuitry, or cause other forms of catastrophic failure. In industrial settings where high-pressure systems are prevalent, such as in oil refineries, it is of utmost importance to be aware of the damage pressure of the sensors in use. Engineers must design safety margins and implement pressure relief mechanisms to prevent accidental overpressurization. When specifying a pressure sensor for a particular application, always consider the maximum possible pressure spikes and ensure that the damage pressure is well above these potential extremes.

Linearity

Linearity describes how closely the output of the pressure sensor follows a straight line relationship with the applied pressure. In an ideal scenario, doubling the pressure would result in exactly double the electrical output. However, in reality, there are often deviations due to factors like material imperfections, manufacturing tolerances, and mechanical hysteresis. A high degree of linearity is desirable as it simplifies calibration and signal processing. In precision measurement applications, such as in a laboratory environment or in the calibration of other pressure-measuring instruments, sensors with excellent linearity are a must. Techniques like polynomial curve fitting are often employed to correct for minor nonlinearities and improve the overall measurement accuracy.

Pressure Hysteresis

Pressure hysteresis refers to the phenomenon where the output of the sensor depends not only on the current pressure but also on the history of pressure changes. When pressure is increased and then decreased, the sensor may not return to the exact same output value for a given pressure. This is caused by factors such as elastic deformation of the sensing element and friction within the sensor assembly. In applications where repeatability and accuracy are critical, such as in pharmaceutical manufacturing or in the control of automated production lines, minimizing pressure hysteresis is essential. Regular calibration and the use of advanced sensor designs with reduced hysteresis characteristics can help mitigate this issue.

Key Environmental Parameters

Temperature Range

The temperature range of a pressure sensor has two main aspects: the compensation temperature range and the operating temperature range. The compensation temperature range is the interval within which the sensor’s output is calibrated to account for temperature-induced changes. Outside this range, the accuracy of the sensor may degrade significantly. The operating temperature range, on the other hand, defines the temperatures at which the sensor can physically function without immediate failure. For example, in automotive engine compartments, sensors must endure high temperatures during operation. In contrast, in outdoor weather stations, they need to operate reliably in a wide range of ambient temperatures, from freezing cold to sweltering heat. Understanding the temperature requirements of different applications helps in selecting sensors with appropriate thermal characteristics.

Stability

Stability refers to the ability of the pressure sensor to maintain a consistent output over time, regardless of environmental factors and wear. It is affected by temperature fluctuations, humidity, vibration, and aging of components. In long-term monitoring applications, such as in structural health monitoring of bridges or in the continuous measurement of gas pressure in a pipeline, sensor stability is crucial. High-quality sensors are designed with materials and manufacturing processes that enhance stability. Regular recalibration and the use of redundant sensor configurations can also contribute to maintaining stable pressure measurements over extended periods.

Other Important Parameters

Accuracy

Accuracy is a measure of how closely the measured pressure value by the sensor matches the actual pressure. It is expressed as a percentage of full-scale error or in terms of an absolute error value. In applications where precise control is required, such as in medical ventilation systems or in the production of microelectronics, high-accuracy sensors are essential. Calibration procedures, both at the factory and in the field, play a significant role in achieving and maintaining the desired accuracy. Advanced compensation algorithms can also be implemented to correct for systematic errors and improve the overall accuracy of the sensor system.

Resolution

Resolution represents the smallest increment of pressure that the sensor can detect and distinguish. A sensor with a high resolution can detect very subtle changes in pressure, which is beneficial in applications like leak detection in gas pipelines or in the measurement of physiological pressures in the human body. When choosing a pressure sensor, the required resolution should be determined based on the specific application needs. Higher resolution sensors may come at a higher cost, so a balance between sensitivity and cost must be struck.

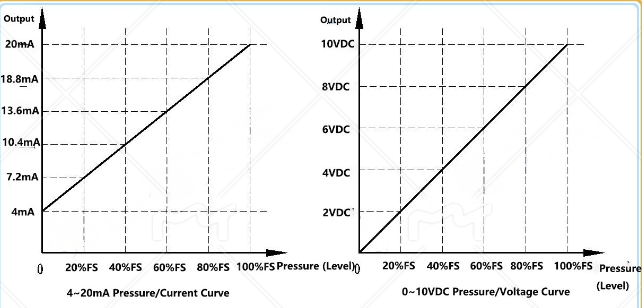

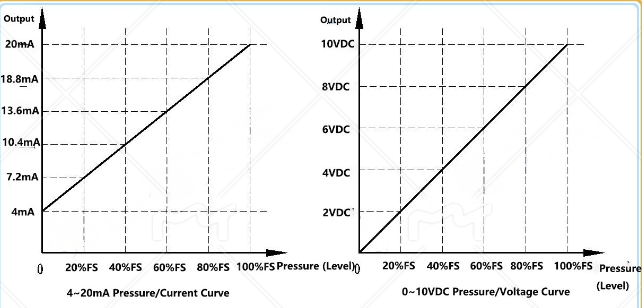

Output Type and Signal Characteristics

Pressure sensors can have various output types, including analog voltage, current, digital signals such as SPI or I2C. Analog outputs provide a continuous voltage or current proportional to the pressure, which is suitable for simple control systems. Digital outputs offer advantages in terms of noise immunity, ease of integration with microcontrollers, and the ability to transmit multiple bits of data. For example, in a smart home automation system, a digital pressure sensor can communicate directly with a central hub, providing real-time pressure data for climate control or water management. Understanding the signal characteristics and compatibility requirements of different output types is essential for seamless integration into a larger system.

Conclusion

In conclusion, the key parameters of pressure sensors are intertwined and play a decisive role in their performance and suitability for various applications. As technology advances, we can expect further improvements in sensor accuracy, stability, and environmental adaptability. Whether you are involved in industrial design, medical technology, or any field that relies on pressure measurement, a deep understanding of these parameters will empower you to make informed decisions. Stay tuned to the latest developments in pressure sensor technology as they continue to shape the way we monitor and control pressure in our modern world.